RUBBER & SILICONE LSR THERMAL EXPANSION

Geschriben am 27-03-2013

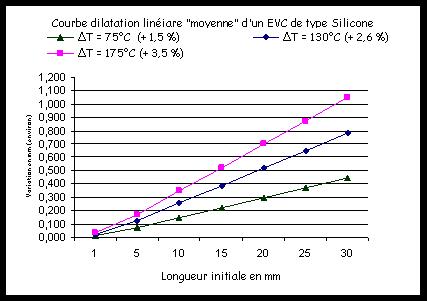

Materials commonly named "RUBBER" are HOT CURED or HIGH TEMPERATURE VULCANISATION ELASTOMERS (HCR or HTV); they expand under temperature increase influence.Their coefficients of linear expansion will directly be function of "loads" rates; they vary according to polymers.

The usual values are from 2 to 4 x 10E-4 (unity = ° KE-1).

For information, silicones we transform into very big quantities have values from 2 to 3 and often closer to 2.

Sample of HCR, which would see its temperature increasing 130 °C, and by ex from 20 °C to 150 °C, would see a average of its initial length L 20 ° becoming :

L 150° = L 20° x (1 + 3 x 0,0001 x delta T ( 130 ) )= L 20° x (1 + 0,039 )

so 3,9 % increase !

This "average" data is very interesting to keep in mind as equipments are studied and detailed (functions of waterproof coupled with significant thermal constraints).

It will be advisable to allow the HCR to dilate volume in best thus… to flow in the space which has been reserved ( compact rubber is not compressible !).

If no, pressures exercised by the HCR component in dilataion process could be too high to exercise important constraints on parts in contact, and because of plastic deformation or break, then lesser performance and break in function return in ambient temperature.

- NEWS N°184, Production of bipolar plates for fuel cells using the LSR injection process, type 3025-40 or EPDM, FKM, ...

- NEWS N° 182 - The CHEVALIER - CLERET - ELTEC Group in summury

- CHEVALIER CLERET ELTEC SILICONES ET CAOUTCHOUCS ECO RESPONSABLES - French Business Climate Pledge 11/12/2017

- FLUORINATED ELASTOMER FKM FPM RUBBER FOR PHARMACEUTICAL USES & FOOD CONTACT APPLICATIONS ALSO STERILIZABLE

- 90, 95 und 10 Jahre Erfahrung für die Entwicklung Ihrer technischen ELASTOMER-Teile: Gummi; SILIKON; LSR

- SELF LUBRICATED NITRILE NBR COMPOUND

- NITRILE NBR FOR GAZ APPLICATIONS NF EN 549

- EXTREME PERFORMANCES FOR RUBBERS & NEW OPPORTUNITIES THROUGH FLS FFLS FLUORO LIQUID SILICONE NEW GRADES AVAILIBITY

- HOW TO GET MOULDED RUBBER PARTS & THERMOPLASTIC TP + SELF BONDING LSR CO INJECTION

- RUBBER PARTS INSPECTION & "IN PRODUCTION" FUNCTIONNEL TESTS

- RUBBER FRICTION

- RUBBER & SILICONE LSR THERMAL EXPANSION

- HYBRIDS : RUBBER BONDING ON METAL (1on2) also named "rubber metal"

- HYBRIDS : LIQUID SILICON RUBBER LSR SELF BONDING ON TP - THERMOPLASTIC (2on2) also named "self bonding lsr silicone"

- http://de.wikipedia.org/wiki/Silicone

- http://en.wikipedia.org/wiki/Synthetic_rubber

- RUBBER REUSE ( HIGH TEMPERATURE VULCANIZATION / CURE ELASTOMERS; SILICONES & LIQUID SILICONE RUBBERS / LSR)

- SILICON AND RUBBER PARTS STORAGE

- SILICON AND RUBBER TEARING

- RUBBER PARTS ASSEMBLING AND MOUNTING

- YOUNG MODULUS FOR RUBBER

- RUBBER RESILIENCE

- RUBBER TANGENT DELTA (TAN DELTA)

- RUBBER TENSILE STRENGTH AND ELONGATION AT BREAK

- RUBBER COMPRESSION SET

- RUBBER HARDNESS MEASUREMENT

- TO BE SEEN IN PHARMAPACK 2012 - Paris

- CUSTOM LSR COLORS

- ELASTOMERS POST CURE

- SILICON AND RUBBER SELF LUBRICATION

- 7 th TECH DAYS

- 6èmes journées techniques